A compact Online-Rheometer for the continuous measurement of MFR and the viscosity function in the polymer production process. The measuring head can be directly integrated with a production extruder.

Online-Rheometer MBR

The MINI BYPASS RHEOGRAPH is a real compact masterpiece that can be easily integrated into existing extruder systems thanks to its small size and low weight.

With a width of just 150 mm and a weight of 30 kg, it does not require any complex fastening, making it easier to install and handle. The innovative die closure system also enables quick and easy die changes, making operation particularly user-friendly.

Good to know

All GÖTTFERT Online-Rheometers are also available for operation in hazardous areas of danger zones 1 and 2 with classification „Gas-Ex: Ex II 2G Ex h IIC/IIB T2 Gb X“ and „Dust-Ex: Ex II 2D Ex h IIIC/IIIB IP65 Ta,max Db X“

Specification

Depending on the operating mode, the following measurement results are provided:

The measurement results are provided in various ways:

CUSTOMIZED TO YOUR REQUIREMENTS

Our modular add-ons also offer an extended option for characterizing materials.

The Shark Skin measuring head is mounted at the bottom of the test barrel instead of the capillary. With this option it is possible to measure exactly at which critical shear rates surface inhomogeneities occur.

The drawability of polymer melts is of utmost importance in many processes of plastics production and processing.

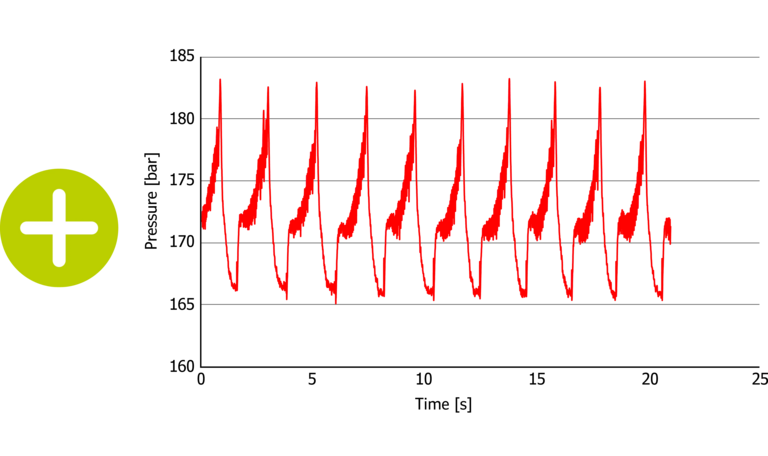

The patented RHEOTENS method has proven to be an extremely sensitive measuring principle that delivers highly reproducible results to show even minimal batch fluctuations.

In addition to the already existing constant speed and constant acceleration, exponential acceleration is now also possible. The determination of the extensional viscosity function according to Prof. Wagner is an integral part of the RHEOTHENS.

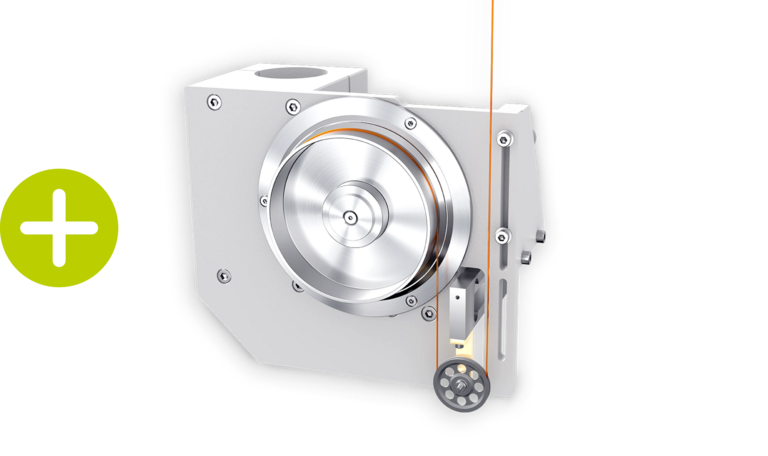

The RHEOTENS is well suited as a processability test for materials used in extrusion or film applications.

Our newly developed HAUL-OFF with a maximum speed of 2000 m/min is particularly suited for the characterization of fibre-grade materials. The system can be operated with constant acceleration or at constant speed steps. The pull-down force is measured via a smooth-running, anti-stick coated measuring wheel on a highly sensitive force transducer.

The measuring head is mounted below the die. The measurement can be carried out parallel to a viscosity measurement.

The viscosity of polymers can also depend on the general pressure level. The Counter Pressure Chamber is mounted behind the die and generates a back-pressure at the die outlet, which is measured with an additional pressure sensor.