For effective analysis of free-flowing thermoset mixtures.

Capillary Rheometer TCR

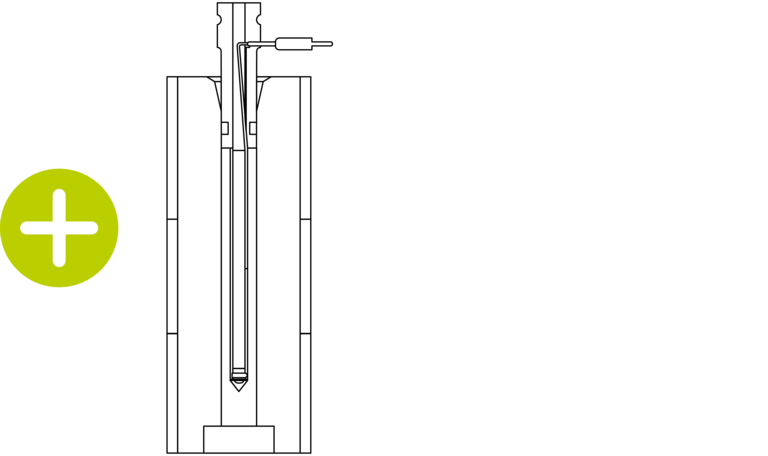

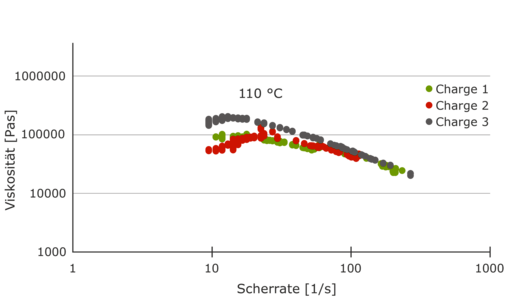

The TCR is a capillary rheometer which was developed for the quality testing of thermosets. The capillary rheometer is particularly suitable for testing and comparing material batches with regard to processing properties. The instrument was developed on the basis of a capillary rheometer with 75kN punch force and the established method of capillary rheometers for plastics and elastomers.

The instrument also consists of a piston/die plate with test chamber and a tool (flow spiral). In order to be able to easily remove the hardened test material, the test chamber is integrated in a conical seat in the die plate for easy removal. By insulating the die plate from the upper half of the tool, different temperatures can be selected between the tool and the die.

Good to know

The test instrument can measure at both constant pressure and constant speed. It consists of a temperature-controlled feed chamber in which the material is preconditioned under defined pressure and volume at a preselected temperature and pressed into a flow spiral with up to five pressure and four thermogradient sensors at a pressure of up to 1600 bar.

The TCR allows an effective determination of the rheological properties in the range of the injection temperature and over the flow path in the mold at crosslinking temperature.

Specification

CUSTOMIZED TO YOUR REQUIREMENTS

Our modular add-ons also offer an extended option for characterizing materials.

The sensor for thermal conductivity is mounted just like a standard piston. The barrel is closed at the bottom during the test. The thermal conductivity measurement of solids or melt is performed under stationary conditions.

Additional temperature control with external thermostat

TCR (Thermoset Capillary Rheometer)

for effective analysis of free-flowing thermoset mixtures

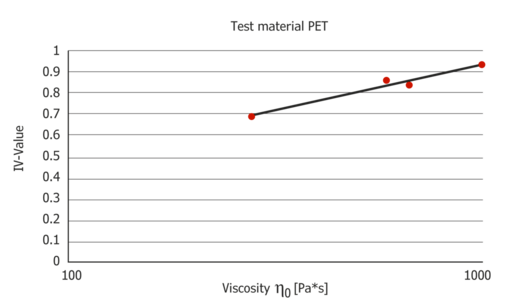

Determination of IV with Capillary Rheometer

The method of measuring the melt viscosity with the capillary rheometer is simple and avoids the environmentally hazardous solvents.

The new RPA

Large Amplitude Oscillatory Shear (LAOS) – Expanded ability to characterize polymers and polymer mixtures with FFT delivers high selectivity