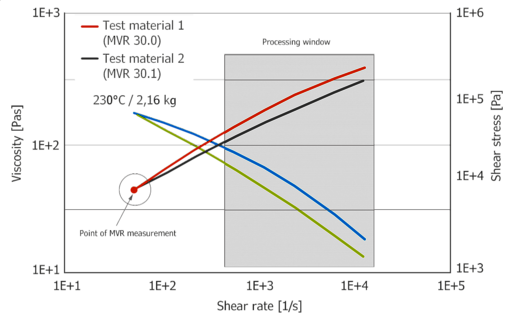

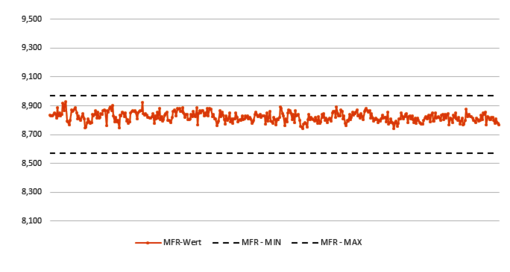

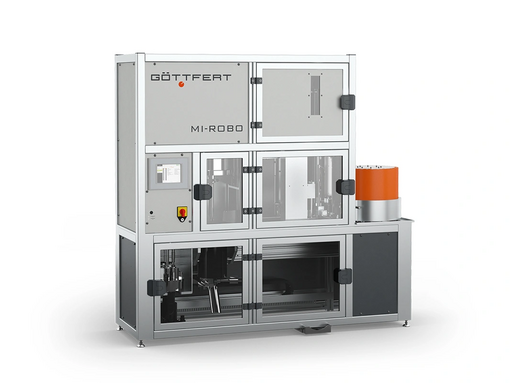

The mi40 marks the beginning of a new era in melt flow rate measurement. The mi40 has been specially developed for incoming goods and quality control (QC) and offers fully automated and highly precise determination of MFR (Melt Flow Rate) and MVR (Melt Volume Rate) according to ASTM D1238 and ISO 1133.

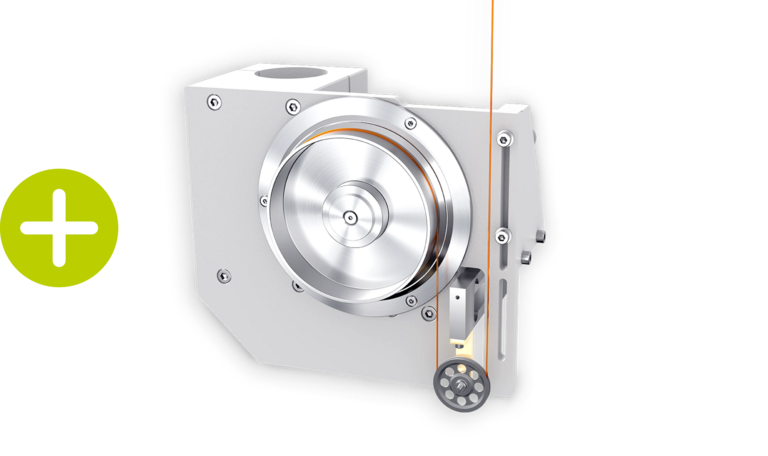

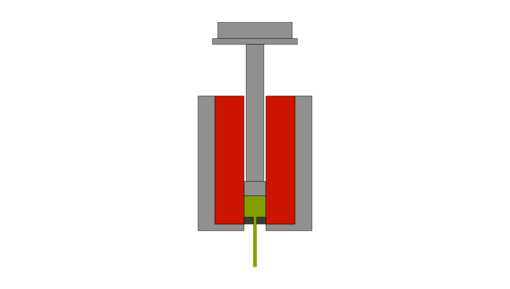

The mi40 combines all the advantages of the proven MI-3 and sets new standards with a higher degree of automation. Due to the powerful drive with a force of up to 60 kg, materials can be pre-compressed or ejected in a force-controlled way. The test-plan-controlled, automatic weight selection with up to eight integrated weights simplifies operation and ensures maximum efficiency. Furthermore, automatic pre-compaction - optionally via weight or drive - minimizes operator influence and increases measuring accuracy.

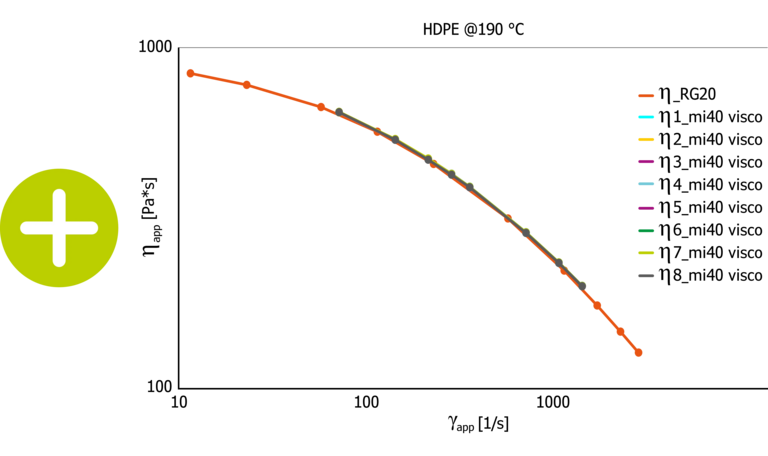

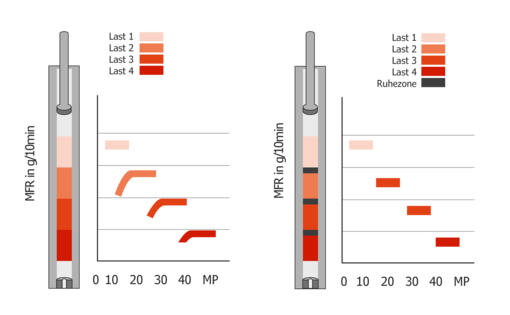

A further highlight

is the fully automatic multi-weight measurement with up to eight different weights per channel filling, which enables a comprehensive analysis in just one test run.

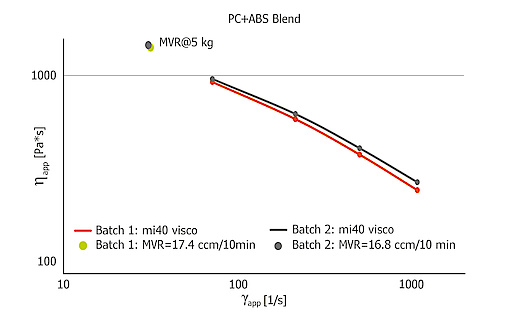

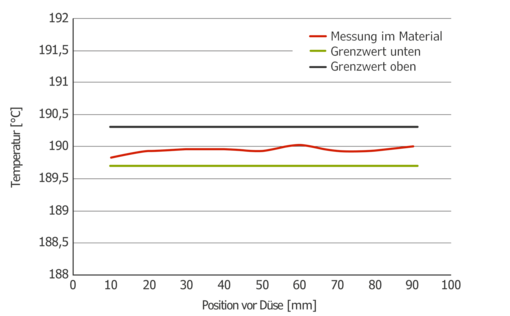

The high-precision displacement measurement guarantees reliable results, even with extremely low or high measured values. The external die guide on the weight guide rod ensures exact, repeatable measurements - even with very sticky materials.