The drawability of polymer melts is of utmost importance in many processes of plastics production and processing.

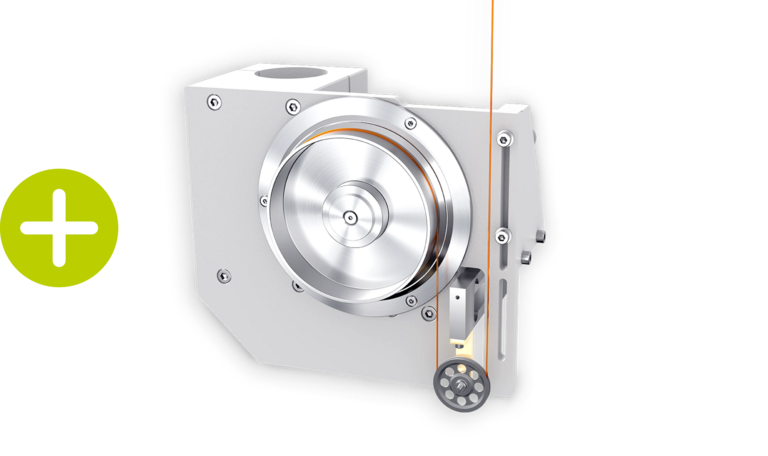

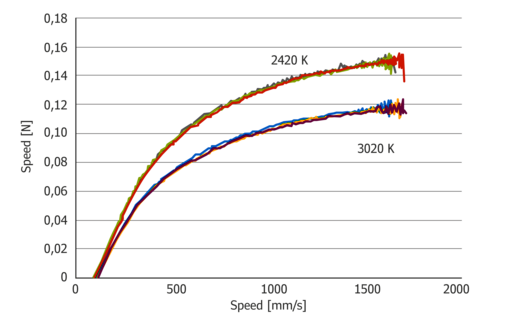

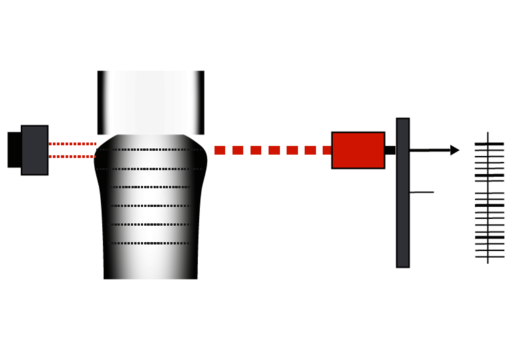

The patented RHEOTENS method has proven to be an extremely sensitive measuring principle that delivers highly reproducible results to show even minimal batch fluctuations.

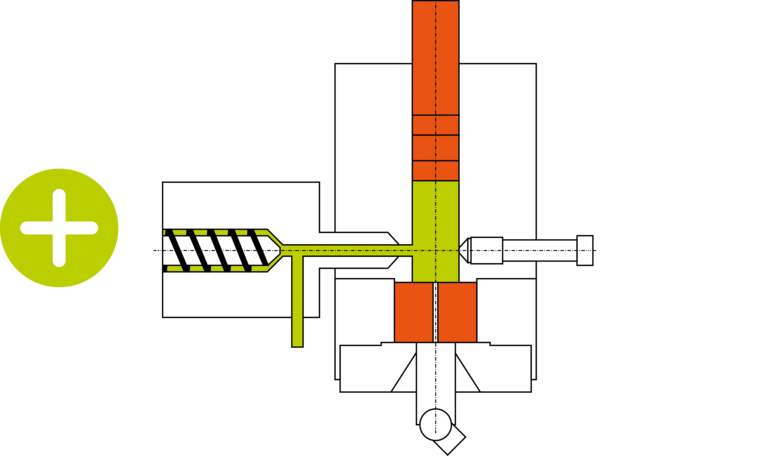

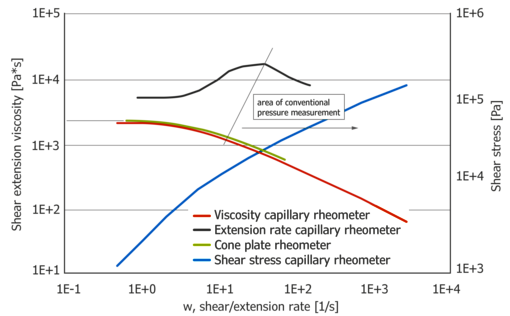

In addition to the already existing constant speed and constant acceleration, exponential acceleration is now also possible. The determination of the extensional viscosity function according to Prof. Wagner is an integral part of the RHEOTHENS.

The RHEOTENS is well suited as a processability test for materials used in extrusion or film applications.

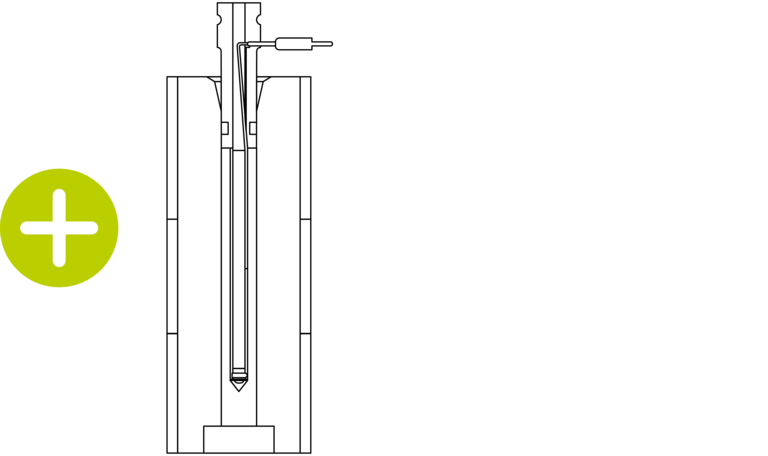

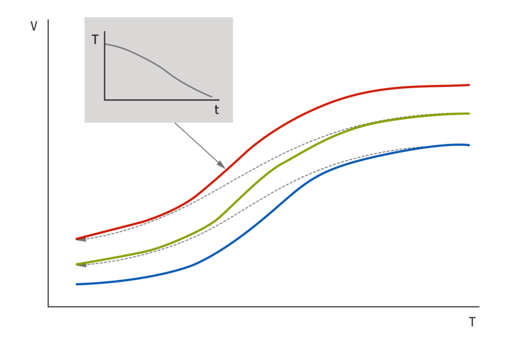

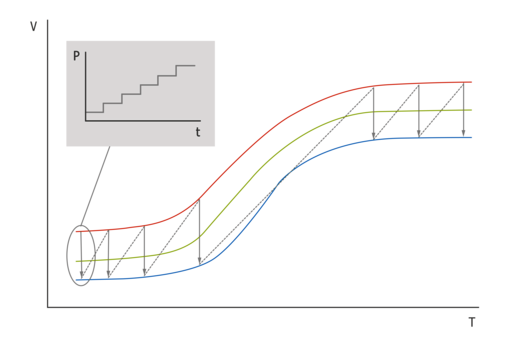

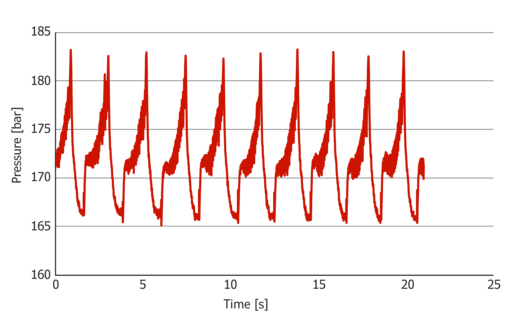

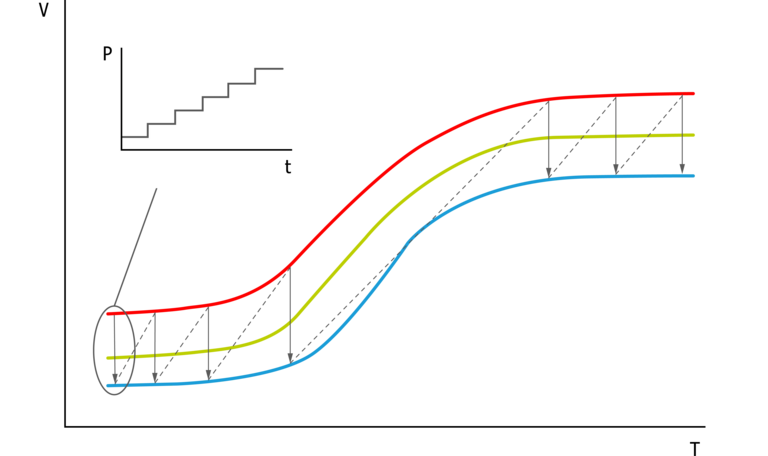

Principle of pVT measurement (isothermal)

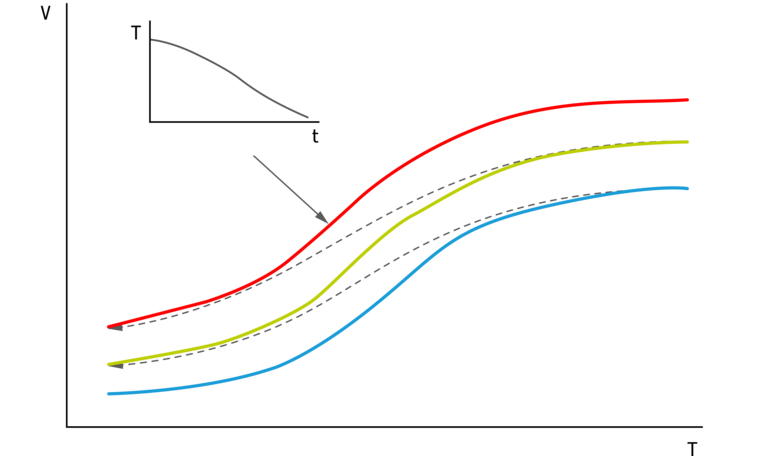

Principle of pVT measurement (isothermal) Principle of pVT measurement (isobaric)

Principle of pVT measurement (isobaric)