Our melt flow index tester offers maximum measuring efficiency using high-quality components.

- ASTM D1238

- ISO 1133

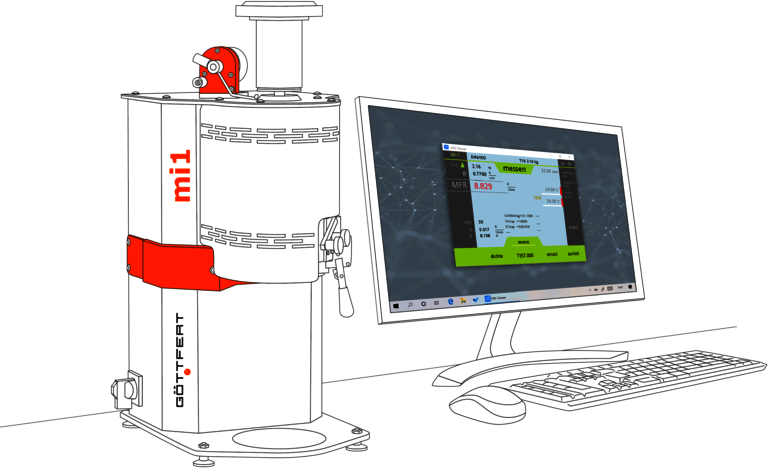

Melt flow indexer mi1

The mi1 is a compact melt index tester that offers maximum measuring accuracy. Thanks to the use of high-quality, measurement-relevant components, it offers reliable and precise results for plastics testing.

Its design enables efficient and cost-effective incoming material and quality control. Thanks to its compliance with the ISO 1133 and ASTM D1238 standards, it is ideal for standardized measurements in laboratories and production.

Good to know

The determination of the melt flow rate (MFR/MVR) is essential for evaluating the processability of plastics. Fast, standardized and reproducible measurement is particularly important in incoming goods inspection and quality control. A compact testing device such as the mi1 enables precise results with minimal space requirements. Thanks to modern sensor technology and high-quality components, it delivers reliable values that support reliable material evaluation and process optimization.

Product features

CUSTOMIZED TO YOUR REQUIREMENTS

Our modular add-ons also offer an extended option for characterizing materials.

Our miCONNECT software is a browser-based platform for workstation-independent management and analysis of measurement data, which can be used without installation.

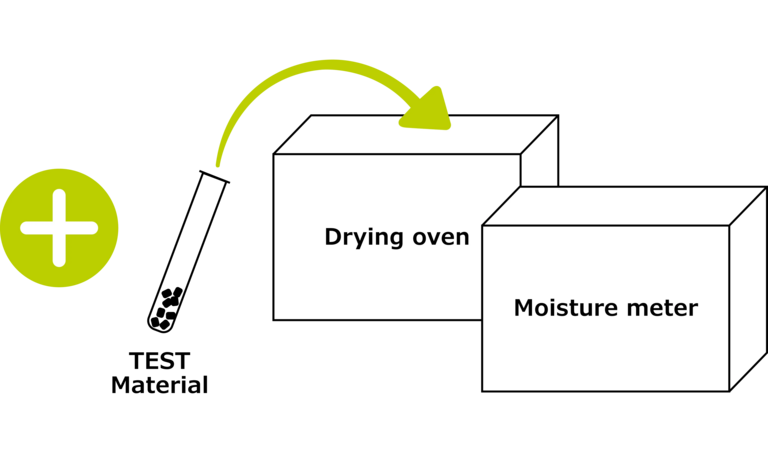

The residual moisture has a considerable influence on the measurement result for certain test materials. Therefore, it is recommended to dry test materials before a IV measurement and to determine the residual moisture.

Directly connected laboratory scale for determination of the melt density.

Intrinsic Viscosity

The intrinsic viscosity (IV), also referred as intrinsic viscosity, or Staudinger index [η]...

Determination of the intrinsic viscosity

The intrinsic viscosity (IV) measured by online capillary rheometers is determined via a correlation relationship between shear viscosity or melt flow rate (MVR) and intrinsic viscosity.