Our semi-automatic melt index tester with fix installed measuring weights

- ASTM D1238

- ASTM D3364

- ISO 1133

Melt flow indexer MI-3

The MI-3 plastometer defines new standards in melt index testing and impresses with its intelligent, user-friendly design. The permanently integrated, fully equipped weight magazine with electric weight lift enables convenient and safe handling. Weight selection is precise and effortless via a selection lever.

Due to the high-precision displacement sensor, even very low or very high MFR/MVR-values can be recorded with high precision. The external piston guidance on the guide rod of the test weight ensures precise and repeatable measurements - even very sticky materials. The test chamber with exchangeable test barrels can be swivelled out for easy filling and cleaning.

Good to know

In addition to the standardized MFR and MVR measurements according to ASTM and ISO, the MI-3 offers a variety of add-ons that create real added value for materials testing. Trust in proven GÖTTFERT quality for maximum precision in material analysis.

Specification

for even more functionality

CUSTOMIZED TO YOUR REQUIREMENTS

Our modular add-ons also offer an extended option for characterizing materials.

Our miCONNECT software is a browser-based platform for workstation-independent management and analysis of measurement data, which can be used without installation.

The residual moisture has a considerable influence on the measurement result for certain test materials. Therefore, it is recommended to dry test materials before a IV measurement and to determine the residual moisture.

Directly connected laboratory scale for determination of the melt density.

The measuring head is mounted below the die. The measurement can be carried out parallel to a viscosity measurement.

Better than ISO 1133

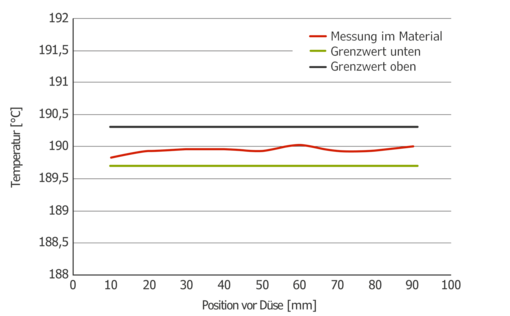

All our melt index testers are equipped with a fast and precise temperature control...

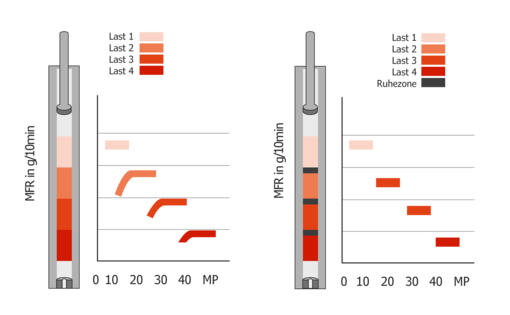

Multi-Load-Measurements

Both our mi40 and MI-ROBO 89.16 can perform automated multi-load measurements with only one filling of...

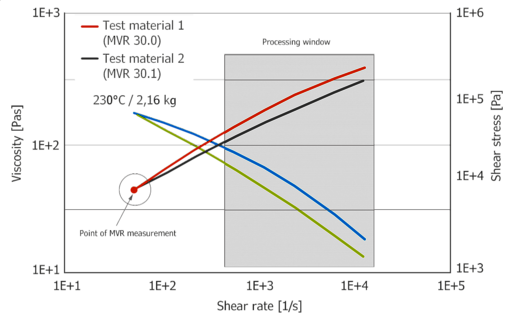

Melt Flow Indexer (MFR/MVR) vs. Capillary Rheometer

A Capillary Rheometer as well as a Melt Flow Indexer (Plastometer) can compare the flow behaviour of polymer plastics...

Intrinsic Viscosity

The intrinsic viscosity (IV), also referred as intrinsic viscosity, or Staudinger index [η]...

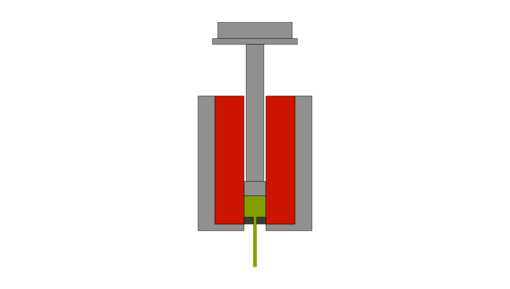

Determination of Melt Flow Index (MFR and MVR)

The melt flow index is a standardized test method to determine the flow rate of plastics at a defined temperature and constant force. The test method...

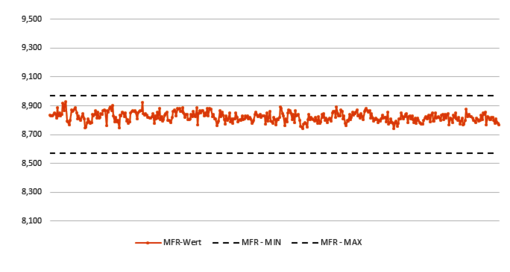

Reproducible and Accuracy of Melt-Index-Tests

GÖTTFERT Melt Flow Testers (Plastometers) are manufactured according to the most modern electronic and mechanical standards with minimal manufacturing tolerances. The result is a testing device which delivers precise and accurate MVR and MFR test results.