Our Rubber Process Analyzer for flexible test design.

- ASTM D6601

- ASTM D6204

- DIN 53529

- ASTM 6048

- ASTM D7050

- ISO 13145

- ASTM D7605

- ASTM D5289

- ISO 6502

Elastomer-Testing RPA VE

The Rubber Process Analyzer (RPA) is used to analyse rubber compounds in a plastic state, during vulcanization and with vulcanized samples. The lower half of the die is controlled with a sinusoidal rotary movement, while the upper half of the die measures the torque and phase angle of the sample.

With 45 years of experience in testing rubber compounds, the RPA delivers precise, repeatable and reliable results.

Depending on the standard and material, the Vulkameter can be equipped with different chamber systems, including both quasi-sealed and hermetically sealed test chambers in bi-conical, Shore and paste versions.

Good to know

Compared to the MDR, the RPA offers significantly more flexibility in test setup. Both the deflection frequency and the amplitude can be set in a wide range under program control. Together with the fast temperature control, tests such as ramp or relaxation tests can be carried out fully automatically in addition to frequency, amplitude and temperature sweeps.

Specification

Measuring methods

for even more functionality

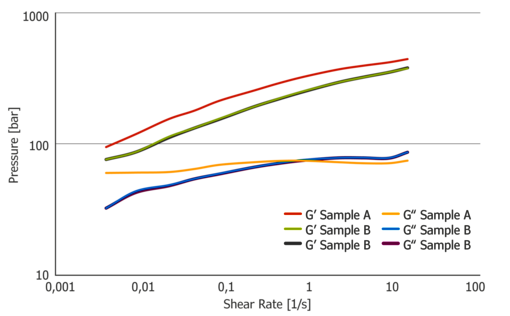

Storage and loss modulus

The storage modulus (G`) measures the energy which is stored in the sample and which will be released after mechanical stress...

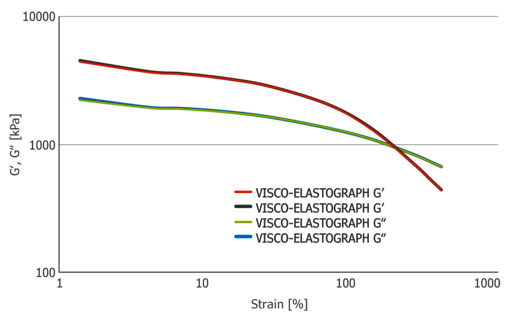

Payne-Effect

The Payne-effect describes the alteration in the polymer properties, which are caused of mechanical stress...

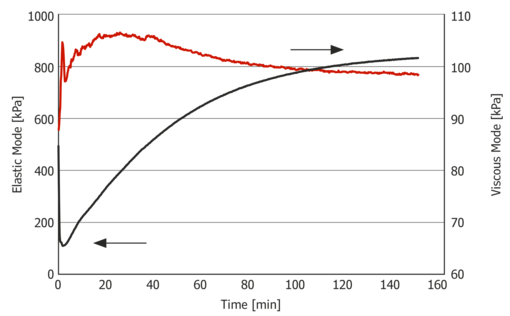

Variable time

Comparable with the usual vulcameter test here the module and the viscosity via the time are being captured...