Measurement of isobaric and isothermal PVT values. PVT stands for pressure, volume and temperature.

- ISO 17744 (PVT)

- ASTM D5930 (TCM)

- ISO 22007 (TCM)

Capillary Rheometer RG20

The PVT500 measures the material-specific correlation of volume, pressure and temperature in accordance with ISO 17744 - a decisive factor for the precise design of forms and the simulation of injection molding processes.

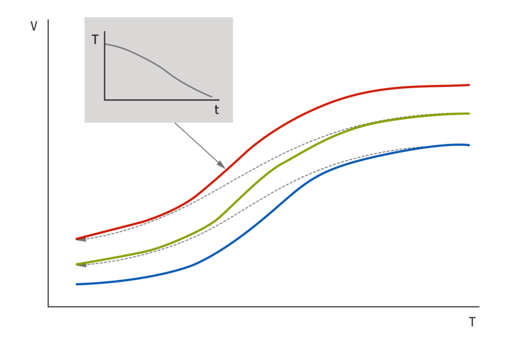

In isothermal tests, the specific volume is determined at a constant temperature as a function of pressure.

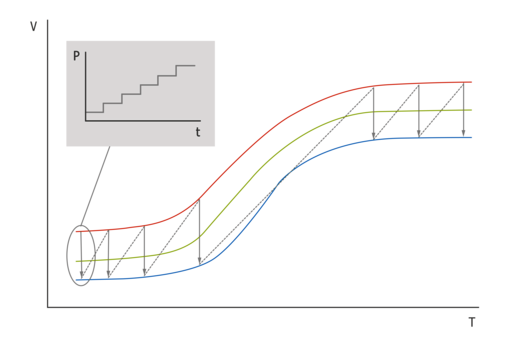

Isobaric measurements keep the pressure constant and measure the volume during cooling - a method that comes very close to the real production process in injection molding.

Thanks to the innovative compressed air cooling, the PVT500 achieves higher temperatures of up to 500°C and cooling rates of up to 30 K/min - significantly faster and more flexible than conventional thermostats.

Good to know

Alternatively, the PVT500 can be operated with an external thermostat to set temperatures below room temperature. It is controlled via the LabRheo PC software, which carries out the measurement fully automatically once the test parameters have been defined. Thanks to real-time monitoring, data can be tracked live during the measurement.

The results are displayed as a PVT diagram and parameterized with the integrated Tait model. The Tait parameters determined can be transferred directly to standard software for simulating injection molding processes.

Specification

CUSTOMIZED TO YOUR REQUIREMENTS

Our modular add-ons also offer an extended option for characterizing materials.

The sensor for thermal conductivity is mounted just like a standard piston. The barrel is closed at the bottom during the test. The thermal conductivity measurement of solids or melt is performed under stationary conditions.

Additional temperature control with external thermostat

PVT isobaric

This procedure is standardized in ISO 17744 for piston operated instruments. Isobaric PVT measurements are performed at constant pressure...

PVT isothermal

In isothermal PVT measurement, the measurement process starts at room temperature after the material is filled at melt temperature and...