Rheology at its smartest! Flexible, compatible, systematic.

Depending on the design variant, our mi2 can be used to run measurements in accordance with the following standards:

- ASTM D1238

- ISO 1133

- ASTM D3364

With automatic weight lifting device

The mi2.2 is more operator friendly than the mi1 thanks to its automatic weight lifting device. This makes it possible to start the measurement automatically after the melting time and to lift the weights at the touch of a button and move them to the start position once the measurement has been completed.

with additional weight magazine

Compared to the mi2.2, the mi2.3 also has a weight magazine that can be loaded with up to 8 test weights. Due to the weight magazine the used test weights do not have to be lifted manually onto the device.

Good to know

Due to the modular design, it is possible to increasingly automate the melt index measurement. The test devices can be used as a stand-alone device or with an adjacent PC to manage the test results.

| Model | mi2.2 | mi2.3 |

|---|---|---|

| Test procedure | Automatic measurement with single load | Automatic measurement with single load and manual weight selection |

| Test chamber | Two heating circuits, electrically heated, temperature sensor PT100 1/3 DIN | |

| Weights | 0.325 - 21.6 kg | |

| Weight guidance | Piston guidance according to EN ISO 1133 / ASTM D1238 | |

| Electrical weight lifting | Yes | |

| Pre-compression and material ejection | Manual with weights (optional) | Partially automated with manual weight selection |

| Display of actual temperature | Manual with weights (optional) | |

| Temperature measurement | via 16-bit converter, resolution from 0 - 320°C: 0.01°C; resolution from 320 - 500°C: 0.1°C | |

| Test barrel | 9.555 (-0.01) mm Diameter | |

| Touchscreen Display | 5.7" (14.48 cm) color VGA touch screen | |

| Test-point recording | Electronic, resolution: 0.025 mm/pulse | |

| Display of results | Numerical | |

| Capillary | 2.095 (+/- 0.003) mm diameter, 8 (+/- 0.025) mm length | |

| Aditional analysis | IV-calculation for the characterization of polyester and polyamide | |

| Melt-cutting device | optional | |

| Capillary plug | optional | |

| Nitrogen purging | optional | |

| Corrosion resistant piston/barrel set | optional | |

| Abrasion resistant piston/barrel set | optional | |

| Pre-compression | Adjustable melting position (optional) | |

| Interface | Ethernet, serial, 1 or 2 x USB (printer, memory) | |

for even more functionality

CUSTOMIZED TO YOUR REQUIREMENTS

Our modular add-ons also offer an extended option for characterizing materials.

Our miCONNECT software is a browser-based platform for workstation-independent management and analysis of measurement data, which can be used without installation.

The residual moisture has a considerable influence on the measurement result for certain test materials. Therefore, it is recommended to dry test materials before a IV measurement and to determine the residual moisture.

Directly connected laboratory scale for determination of the melt density.

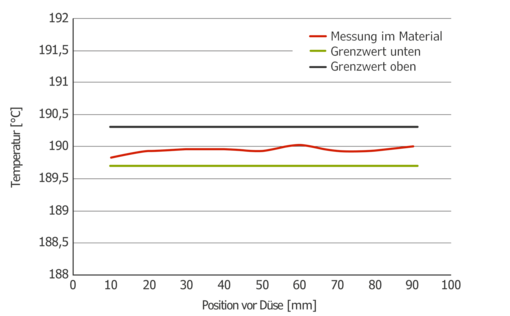

Better than ISO 1133

All our melt index testers are equipped with a fast and precise temperature control...

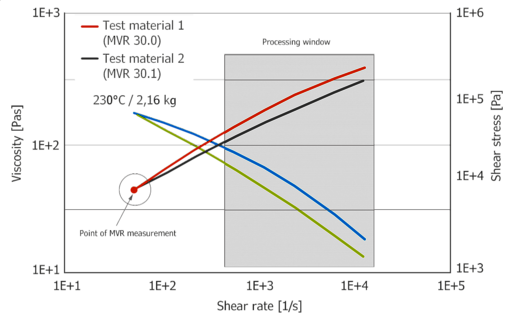

Melt Flow Indexer (MFR/MVR) vs. Capillary Rheometer

A Capillary Rheometer as well as a Melt Flow Indexer (Plastometer) can compare the flow behaviour of polymer plastics...

Intrinsic Viscosity

The intrinsic viscosity (IV), also referred as intrinsic viscosity, or Staudinger index [η]...

Determination of Melt Flow Index (MFR and MVR)

The melt flow index is a standardized test method to determine the flow rate of plastics at a defined temperature and constant force. The test method...

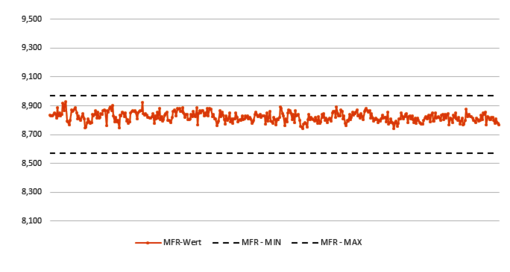

Reproducible and Accuracy of Melt-Index-Tests

GÖTTFERT Melt Flow Testers (Plastometers) are manufactured according to the most modern electronic and mechanical standards with minimal manufacturing tolerances. The result is a testing device which delivers precise and accurate MVR and MFR test results.