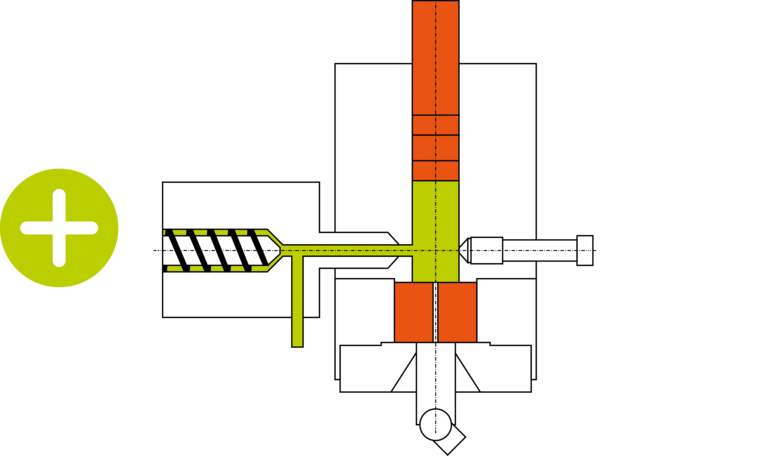

The counter pressure viscometer, or GDV for short, consists of two capillary rheometers that are connected via a connecting chamber. This allows the viscoelastic behaviour to be characterized depending on the back pressure.

- ISO 17744 (PVT)

- ASTM D5930 (TCM)

- ASTM D5099 (Gummi)

- ISO 11443 (Viskosität)

- ASTM D3835 (Viskosität)

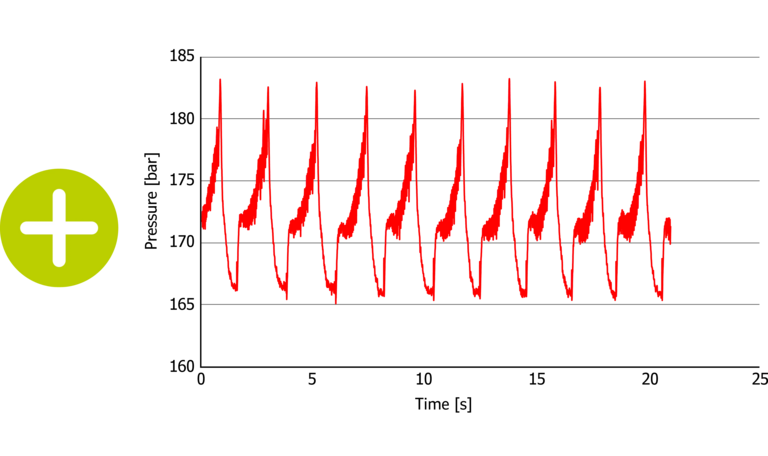

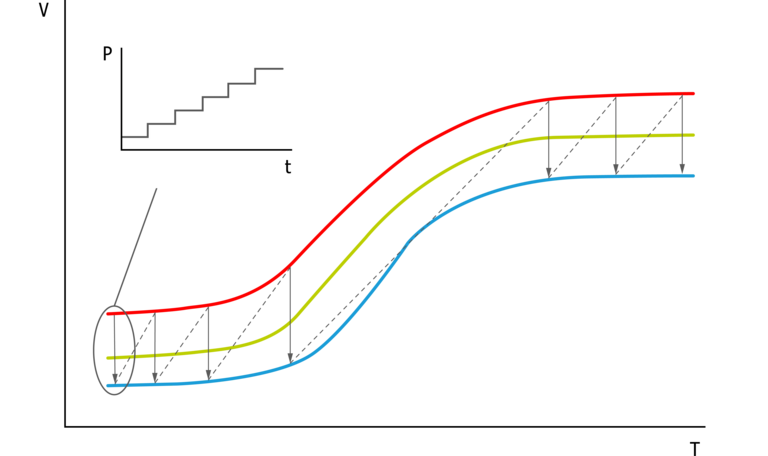

Principle of pVT measurement (isothermal)

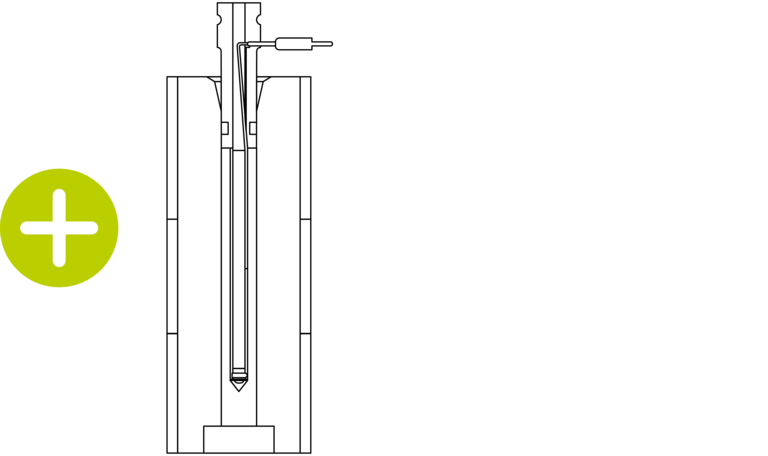

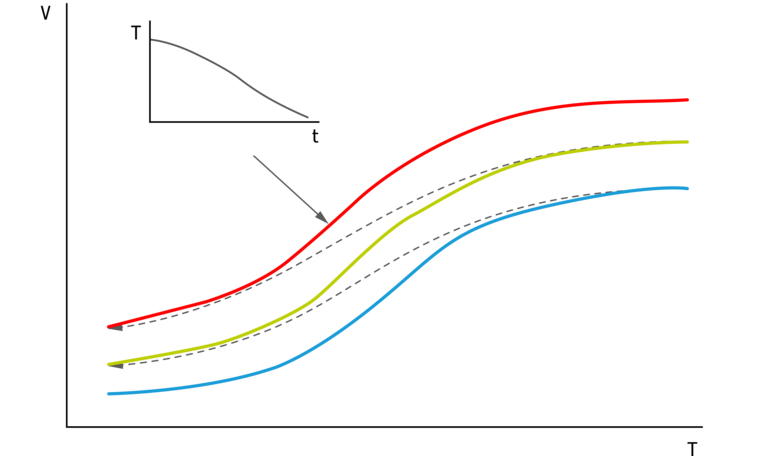

Principle of pVT measurement (isothermal) Principle of pVT measurement (isobaric)

Principle of pVT measurement (isobaric)