The RG25 auto is a semi-automated capillary rheometer which supports the operator with a high number of viscosity measurements in low and high shear rate range by automation of filling, measuring and cleaning. The tester is particularly used in the quality assurance of polymers.

The semi-automated capillary rheometer enables the user to carry out automated viscosity measurements. The main automation modules focus on barrel cleaning, capillary closing as well as capillary pre-cleaining.

Furthermore, we offer external cleaning modules for the rheological tester, such as plunger cleaning. Optionally, the capillary rheometer can be equipped with 25kN or 50kN test force and configured between the single-channel systems with a diameter of 9.5mm or 12mm.

The basic instrument of GÖTTFERT capillary rheometers is designed to carry out viscosity measurements with plastics, rubbers and a variety of other materials. By using modular Add-Ons additional characterization possibilities can be used.

The measuring head is mounted below the die. The measurement can be carried out parallel to a viscosity measurement.

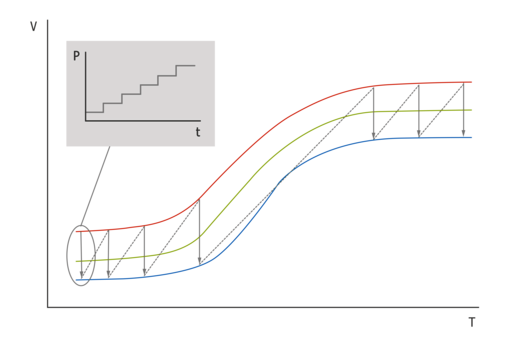

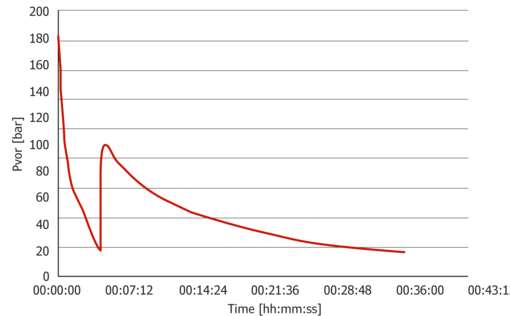

This procedure is standardized in ISO 17744 for piston operated instruments. Isobaric PVT measurements are performed at constant pressure...

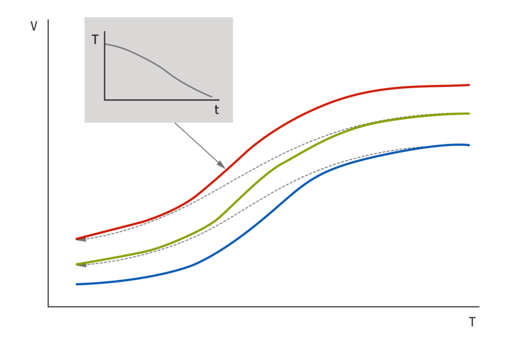

In isothermal PVT measurement, the measurement process starts at room temperature after the material is filled at melt temperature and...

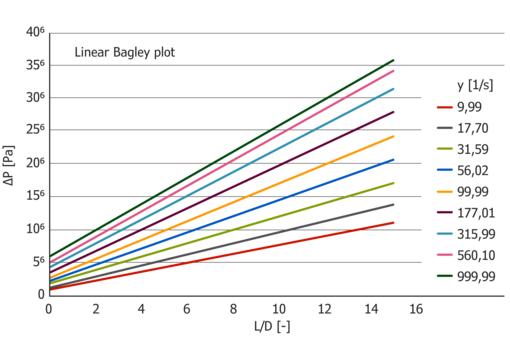

The Bagley correction is needed to calculate the inlet pressure drop when round hole capillaries...

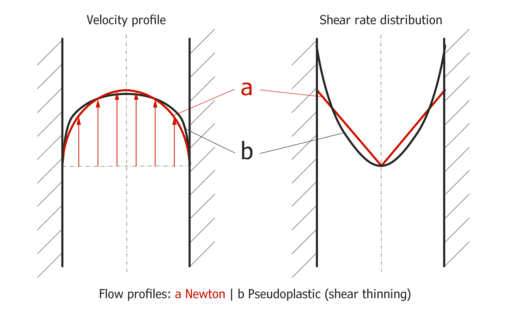

Due to shear thinning of polymer melts with pseudoplastic flow behaviour a strong flection of the...

Plastics have the property of aging through thermal or mechanical stress...

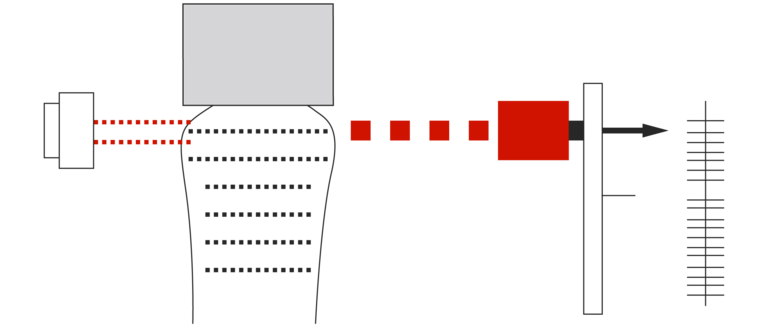

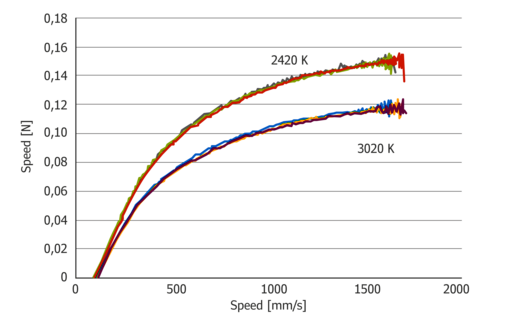

The melt strength (elasticity) is determined by withdrawing an extruded strand of capillary rheometer...

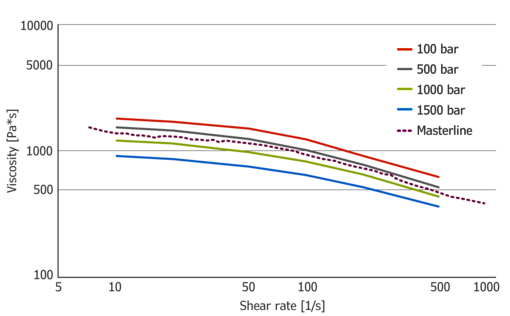

The counter pressure chamber, which offered by GÖTTFERT as an optional Add-on ...

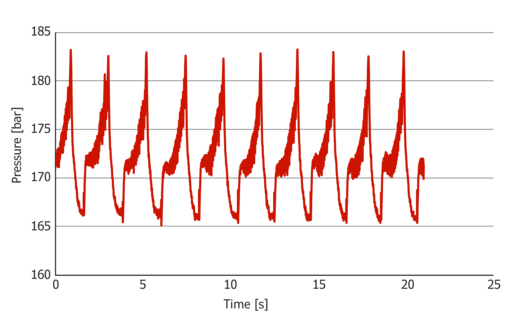

The Shark-Skin effect occurs during the extrusion of plastics, elastomers or food and manifests...

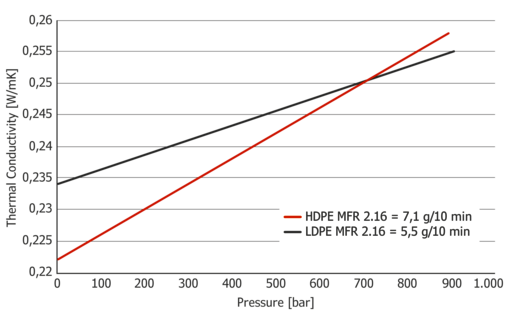

The measurement of the thermal conductivity is carried out by means of a probe...

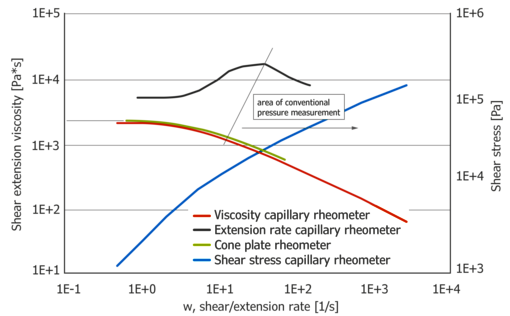

The extensional viscosity can be calculated with measured data of a capillary rheometer...

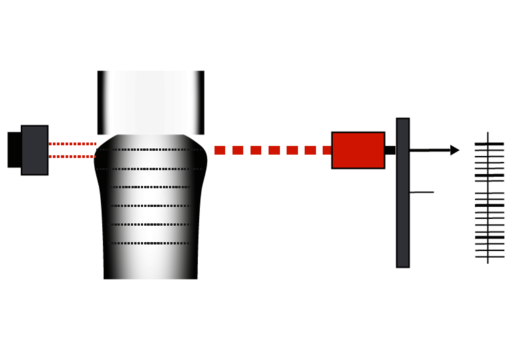

The Die Swell measurement is one of many available add-ons for the series of GOETTFERT capillary rheometers...